BEAUTIFUL TILE AND DESIGNERS WHO CARE

WE'VE GOT YOU COVERED

Book a Free In-Store Design Appointment

We have an amazing Design Team, full of Interior Decorating graduates, with a passion for creating beautiful spaces. Our Showroom Designers bring energy, experience, and creativity to every project, ensuring you make selections that you’ll love for years to come.

Oh and one more thing - our Design Team does not work on commission, meaning you’ll never be pressured to buy something you don’t love.

If the thought of choosing tile for your space is overwhelming, let us help you!

TOP SELLERS

-

Classic Vintage White

Regular price From $7.89Regular priceUnit price / per -

Tint Sea Glass

Regular price $0.00Regular priceUnit price / per -

Laura Ashley Wicker Twine

Regular price $0.00Regular priceUnit price / per -

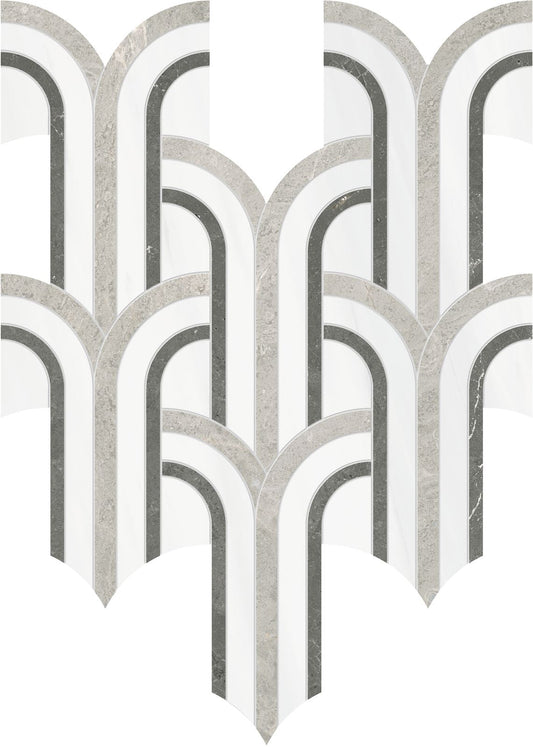

Malta Glacier

Regular price $22.95Regular priceUnit price / per -

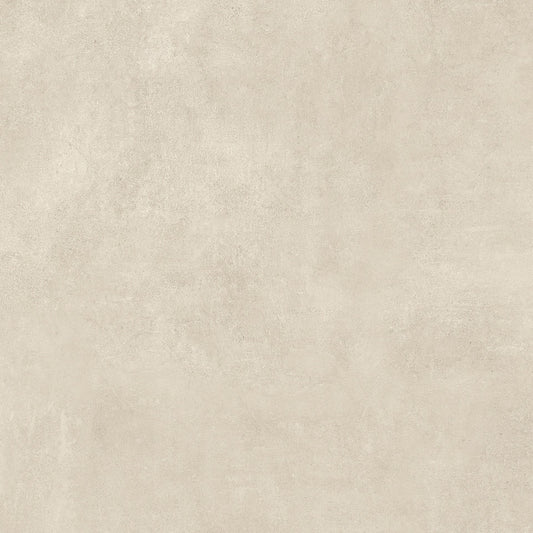

Utopio Florence Mist

Regular price $106.94Regular priceUnit price / per -

Glocal Ginger

Regular price From $10.30Regular priceUnit price / per -

Nord Chromium

Regular price From $7.03Regular priceUnit price / per -

La Marca Nero Venato

Regular price From $7.65Regular priceUnit price / per

Come Visit Us!

OAKVILLE

1360 Speers Road, Oakville, On L6L 5V3

905-465-1650

Showroom Hours:

Monday 08:00am - 5:00pm

Tuesday 08:00am - 5:00pm

Wednesday 08:00am - 5:00pm

Thursday 08:00am - 7:00pm

Friday 08:00am - 5:00pm

Saturday 09:00am - 4:00pm

Sunday 11:00am - 4:00pm (warehouse closed)

Warehouse open at 7AM Mon-Fri

MISSISSAUGA

505 Queensway East, Mississauga, ON L5A 4B4

905-277-1760

Showroom Hours:

Monday 08:00am - 5:00pm

Tuesday 08:00am - 5:00pm

Wednesday 08:00am - 5:00pm

Thursday 08:00am - 7:00pm

Friday 08:00am - 5:00pm

Saturday 09:00am - 4:00pm

Sunday 11:00am - 4:00pm (warehouse closed)

Warehouse open at 7AM Mon-Fri

Burlington

2202 Industrial Street, Burlington, ON L7P 0N6

905-633-9634

Showroom Hours:

Monday 08:00am - 5:00pm

Tuesday 08:00am - 5:00pm

Wednesday 08:00am - 5:00pm

Thursday 08:00am - 7:00pm

Friday 08:00am - 5:00pm

Saturday 09:00am - 4:00pm

Sunday 11:00am - 4:00pm (warehouse closed)